Me ke kaʻina hana o ka ʻenehana ma Kina, ke kau mau nei nā kānaka i nā koi kiʻekiʻe no ka maikaʻi o ka welding o ka welding lima.ʻAʻole hiki i ka wili lima argon arc kuʻuna ke hoʻokō i nā koi kiʻekiʻe o ka poʻe no ka maikaʻi a me ka maikaʻi.

ʻO ka maʻamau no ke ana ʻana i ka maikaʻi o ka mīkini wili lima paʻa i nā ʻaoʻao āpau.Ma kekahi ʻaoʻao, ʻo ia ka maikaʻi o ka welding.Ma kekahi ʻaoʻao, ʻo ka hana mīkini,

1.Welding maikaʻi

ʻO ka wikiwiki o ka welding o argon arc welding he lohi a maʻalahi hoʻi e hana i ka deformation;ʻO ka hoʻopaʻa lima lima laser he wikiwiki, ʻaʻole maʻalahi ke hoʻololi, paʻa loa ka weld, me ka ʻole o ka welding scar, nani a maʻalahi ka hui kuʻi, a paʻa a paʻa ka hana.

ʻO nā kālena ʻenehana elite o ka ʻoihana i ka ʻoihana e hoʻokō i nā mea hou a puni a me ka hoʻomaʻamaʻa ʻana i nā mea hana kuʻi lima lima lima, e hāpai ana i ka hoʻomaikaʻi ʻana i ka ʻenehana welding, e hāʻawi ana i nā mea kūʻai aku me nā lako hoʻoheheʻe lima lima lima kiʻekiʻe, a lawe mai i kahi ʻike kuʻihao hou.ʻO ka wikiwiki o ka hoʻoheheʻe ʻana o ka welding paʻa lima laser he 5 a 10 mau manawa ʻoi aku ka wikiwiki ma mua o ka wili kuʻuna.

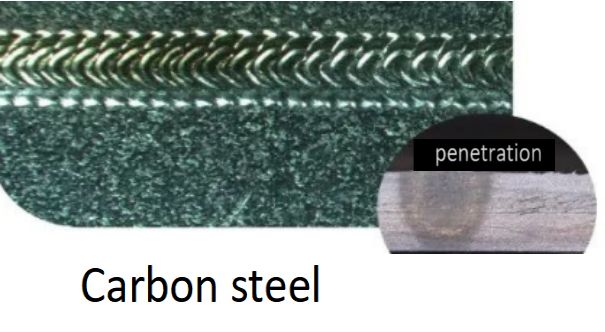

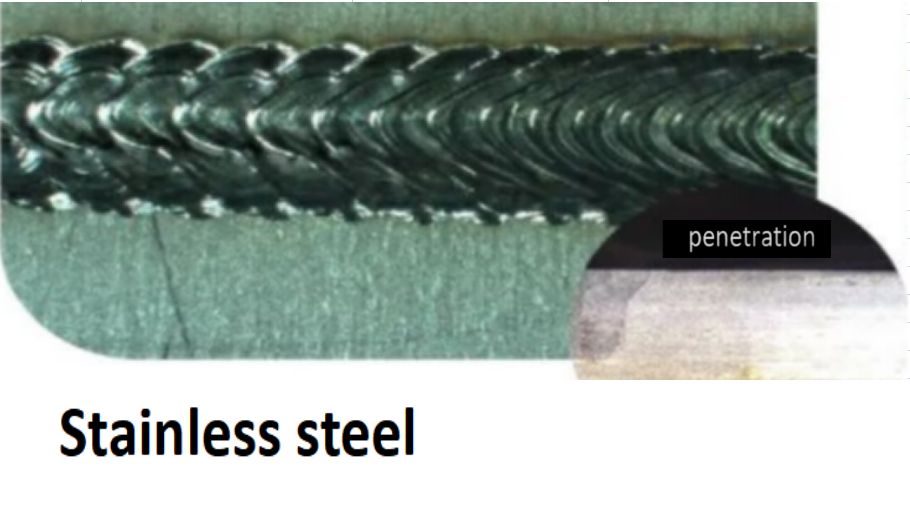

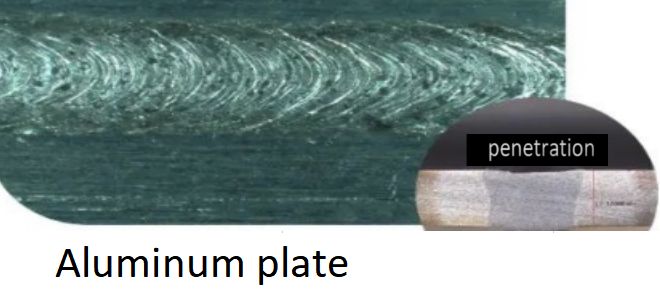

| Mea waiwai | Ke komo ʻana | Ka māmā holo |

| Kila kohu ʻole | 4mm | 7mm/s |

| ʻO ka hao hao | 4mm | 6mm/s |

| Aluminum | 3mm | 7mm/s |

| Pepa Galvanized | 4mm | 7mm/s |

| keleawe | 3mm | 8mm/s |

| keleawe | 1mm | 8mm/s |

2.Machine quality - papa ma ka papa nānā

Ma mua o ka haʻalele ʻana i ka hale hana, ua hala kēlā me kēia mīkini kuʻi lima lima i ka 72 hola kiʻekiʻe kiʻekiʻe (35 ° C) hoʻāʻo ʻelemakule māmā, a ʻo ka 12 hola hoʻomau hoʻomau 99% hoʻāʻo paʻa mana.He 100,000 mau hola ke ola lawelawe o ka chip laser.Ua hala ka huahana i nā ho'āʻo hilinaʻi piha / EMC ho'āʻo, a paʻa a paʻa.

Ka manawa hoʻouna: Nov-15-2022