Nā mea hoʻonā lāʻau lapaʻau

Mīkini ʻoki ʻoki Laser no nā mea hana hoʻolālā lāʻau MPLC6045

ʻenehanaParameters:

| ʻO ka wikiwiki hana kiʻekiʻe | 300mm/s(X1);100mm/s(X2);50mm/s(Y;50mm/s(Z;600rpm(θ) | |||

| Kaulana pololei | ±3um(X1;;±5um(X2);±3um(Y); ±3um(Z;;±15arcsec(θ) | |||

| Ka pololei o ka hoonoho ana | ±1um(X1;;±3um(X2);±1um(Y;;±1um(Z;;±3arcsec(θ) | |||

| ʻOki ʻana i ka laula hili | 20um~30um; | |||

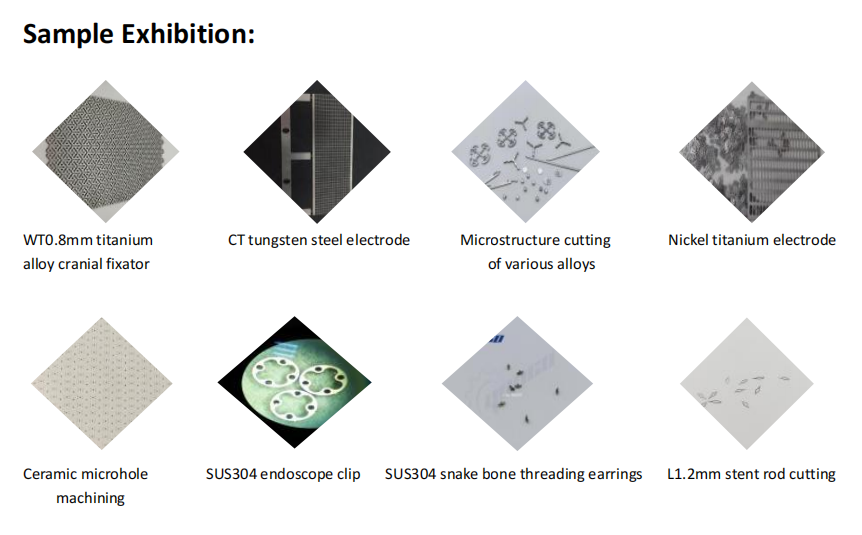

| Mea mīkini | 304&316L&Ni-Ti&L605&Al&Gu&Li&Mg&Fe etc. | |||

| Paipu blank lōʻihi | <2.5m (hiki ke hoʻopilikino ʻia ke kākoʻo kākoʻo); | |||

| Ka mānoanoa o ka pā | 0~1.5±0.02 mm; | |||

| Laina hana paipu | Φ0.3~Φ7.5&Φ1.0~Φ16.0±0.02 mm; | |||

| Laina hana mokulele | 200mm(300mm)*100mm; | |||

| laula hana | 0~300mm&0~600mm (hiki ke hana ʻia nā huahana lōʻihi e ka hoʻokaʻawale ʻana ala); | |||

| Ka lōʻihi o ke koena mea | 60mm; | |||

| ʻAno laser | Laser fiber; | |||

| Ka lōʻihi hawewe laser | 1030-1070±10nm; | |||

| mana laser | 200W&250W&300W&500W&1000W&QCW150W no ke koho; | |||

| lako mana lako | 220V± 10%, 50Hz ;AC 25A (kahi kaapuni nui); | |||

| ʻano waihona | DXF&DWG&STP&IGS; | |||

| Nā ana lako | 1200mm(&1800mm)x1300mmx1750mm; | |||

| Ke kaumaha o ka lako | 1500Kg; | |||

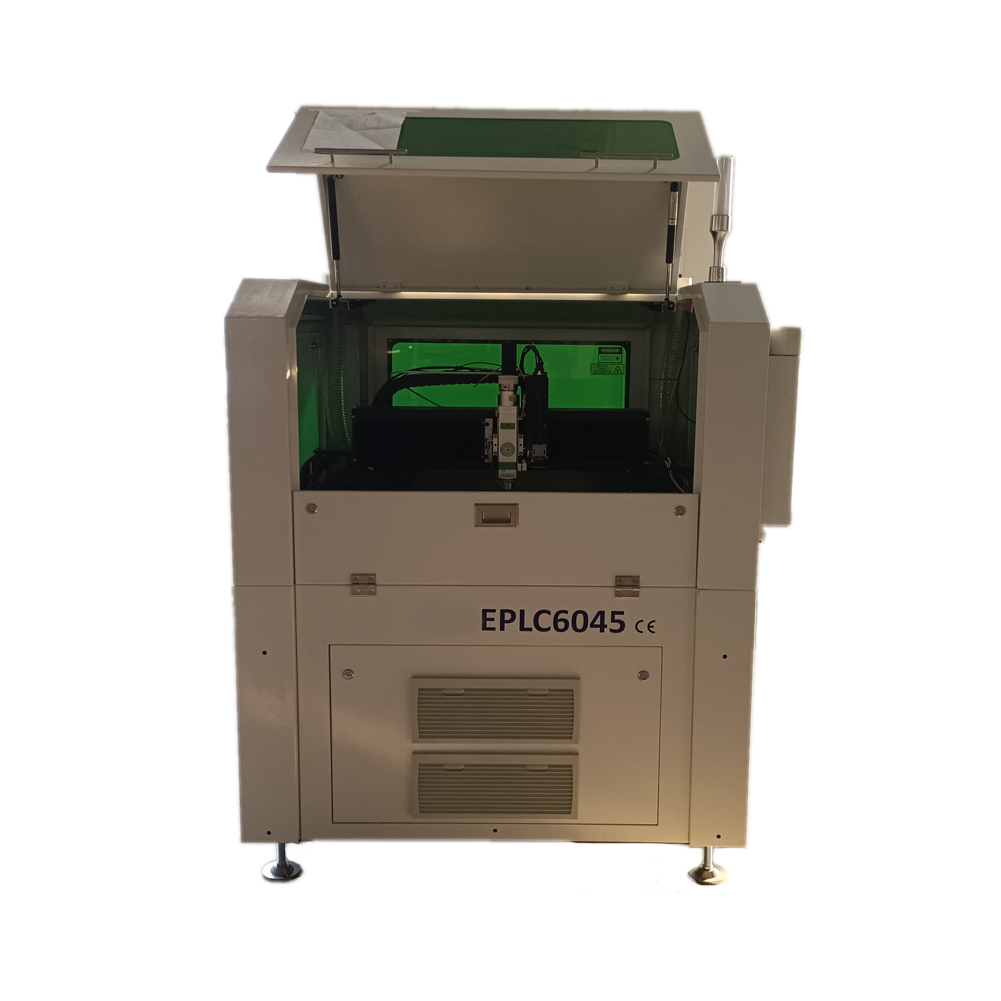

EPLC6045

Hiki ke hoʻololi ikaika

①Me ka ʻoki maloʻo laser a me ka ʻoki ʻoki ʻana a me ka hoʻoheheʻe ʻana a me ka slotting a me nā mea hiki ke hana maikaʻi.

②Hiki i ka mīkini 304&316L&Ni-Ti&L605&Li&Mg&Al&Cu&Fe&Ceramic a me nā mea ʻē aʻe

③Hiki i ka mīkini mokulele a me nā mea kani o ka ʻili

④E hāʻawi i kahi kūlana pālua a me ka ʻike maka mīkini a me ka loaʻa ʻana a pani ʻia i ka blanking a me ka hoʻouka ʻana a me ka wehe ʻana i ka ʻōnaehana a me ka nānā ʻana i ka mīkini a me nā hana like ʻole.

⑤Hoʻolako ʻia me ke poʻo ʻokiʻoki laser maikaʻi i hoʻomohala ponoʻī ʻia me ka nozzle ʻoi a palahalaha & kūpono me ke poʻo ʻoki laser i loaʻa i ke kūʻai aku.

⑥Hoʻolako ʻia me ka ʻōnaehana polokalamu 2D & 2.5D & 3D CAM i hoʻomohala pono ʻia no ka micromachining laser

E hahai i ka manaʻo hoʻolālā o ergonomics, maʻalahi a pōkole

Laulā noi:

ʻO ka micromachining laser o nā mea hōʻoki a me nā mea orthopedic e like me ka endoscope paʻa a me ka scalpel ultrasonic & endoscope & stapler a me ka mea suture a me ka drill palupalu & planer & puncture needle & nose drill

Kiekie precision machining:

①ʻOki liʻiliʻi ka laula o ka humuhumu: 18~30um

②High machining pololei: ≤ ± 10um

③Maikaʻi maikaʻi o ka ʻoki ʻana: ʻaʻohe burr a me ka ʻoki maʻalahi

④Machining kiʻekiʻe: ʻoki ʻoki hoʻokahi ma ka paia o ka ʻaoʻao ʻaoʻao a me ka hoʻomau ʻana i ka mīkini hana hānai

Hoʻolālā maʻalahi

①E hahai i ka manaʻo hoʻolālā o ergonomics, maʻalahi a pōkole

② Hāʻawi i ka hana koho o ka ʻōnaehana ʻike mīkini i ka manawa maoli e nānā i ka pūnaewele i ke kaʻina hana machining laser.

③Hoʻolikelike nā lako polokalamu a me nā hana lako, kākoʻo i ka hoʻonohonoho hana pilikino a me ka hoʻokele hana akamai.

④E kākoʻo i ka hoʻolālā hou mai ka pae ʻāpana a i ka pae ʻōnaehana

⑤Open type control & laser micromachining software system is easy to operate & intuitive interface

Nuhou pili

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur